Turbine Technology

Enhanced Turbine for Air and Water

Maximize Airflow

Slow the fan speed

Restrict Chemical Waste

Understanding the needs and priorities of our customers and operators is at the forefront of Slimline Manufacturing. We have built a trusted reputation founded on a progressive approach to customer support and technological performance.

Turbo-Mist™Airblast technology maximizes airflow while restricting chemical recycling and waste. Our patented turbine technology is designed to prevent the loss of air consistency throughout the RPM range of the fan output, allowing you to slow the speed of the fan while retaining consistency. This allows for accurate targeting of airflow, maximizing coverage at a lower horsepower, saving fuel and increasing yield.

Premium Air Quality

Our front air intake turbine design compresses air to guarantee even distribution through both outlets. Our nozzles are mounted out of the airstream to provide unobstructed air that shears the water. The turbine is engineered to draw clean air from between the tank and the fan housing, producing clean, non-contaminated air that doesn’t recycle the spray. This increases equipment safety, reduces dust and debris circulation, and results in accurate solution distribution and maximum crop protection.

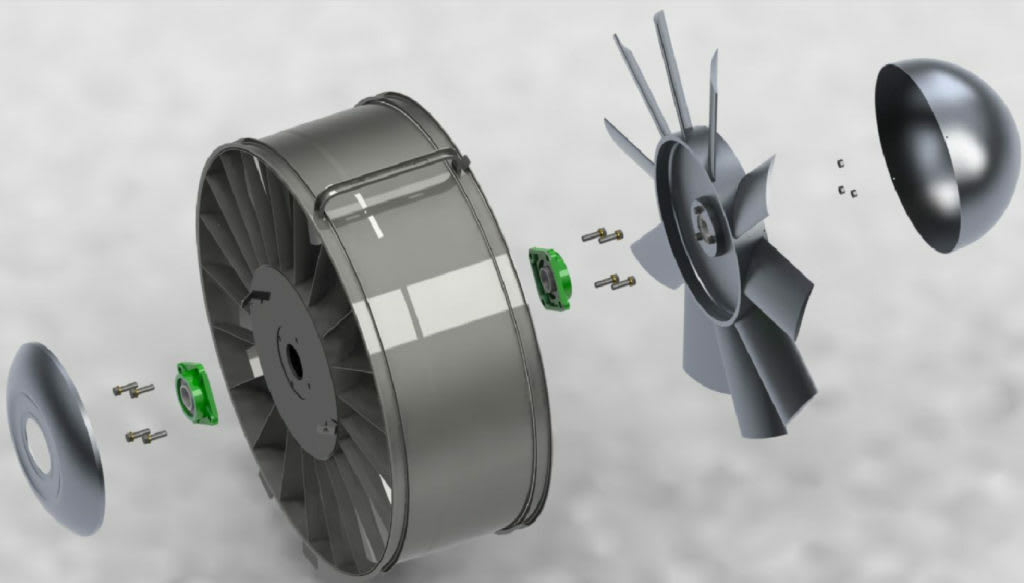

Designed with air straighteners, our system allows the machine to suck in twice as much air as it exhausts, building pressure within the outlets to produce maximum air flow for the fan, ensuring air consistency and premium air quality. The fan is precision machined to maintain a blade clearance of 50 thousandths of an inch to retain and control air pressure and improve overall performance.

Durability

The cast aluminum fans prevent rust and deterioration, ensuring durability and reliability for the lifetime of the sprayer. We use a heavy-duty flange on an isolated gearbox to absorb operational effects and prevent the transfer of mechanical vibrations. While ensuring superior air quality and consistency, this also protects the gearbox and its major components, reducing maintenance and increasing the lifespan of the equipment.

At Slimline, the Gear Up Throttle Down concept involves selecting a higher gear to maintain speed and calibration. By shifting to a higher tractor gear (gear up) and slowing engine speed (throttle down) to maintain your desired speed, you can save up to 40% on fuel, 30% on chemicals and improve coverage by 30%. Save fuel and hit your targets.